.png)

ECSC has a group of CAE experts, which is highly professional in various industries including manufacturing, mechanical, and transportation, aerospace, biological, energy and semiconductor. We offer a range of engineering services and finite element analysis, including forging analysis, stamping analysis, casting analysis, structural analysis, fatigue analysis, CFD analysis, welding analysis, vibration analysis etc.

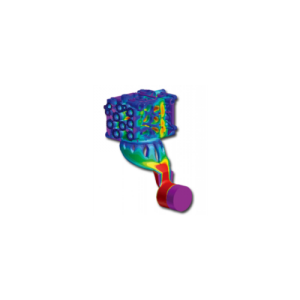

Simufact Forming

.png)

Simufact Forming has been developed to meet the needs of the forming industries. There are Finite Volume method (FV) and Finite element method(FE) for analysis, and a simulation tool for hands-on professionals working with forming technology. The core solution for the simulation of all kinds of forming processes, which including hot forging, cold forming, sheet metal forming, rolling, ring rolling, open die forging, mechanical joining, heat treatment and pressure welding. Simufact Forming's standard user interface allows for the software to be easily used and therefore, to become an engineering tool for developers of dies or processes whose daily work is supported and simplified. With a few clicks, all standard-forming processes can be simulated and evaluated. It can significantly advance in terms of energy efficiency, material saving and lighter components.

ProCAST

.png)

ESI’s Casting Simulation Suite, ProCAST, provides a complete set of solutions for the foundry industry. An advanced tool which is the result of more than 25 years of collaboration with major industrial partners and academic institutions across the world, ProCAST offers an extensive suite of modules and foundry tools to meet today’s challenging industrial requirements. Based on the powerful Finite Element Technology, ProCAST enables predictive evaluations of the entire casting process, including filling and solidification defects, mechanical properties and complex part distortion. It enables rapid visualization of effects of design changes and provides a basis for correct decision-making, from the earliest stages of the manufacturing process. ProCAST enables the modeling of all casting processes for all castable alloys, and also addresses other foundry relevant manufacturing process like core blowing & heat treatment.

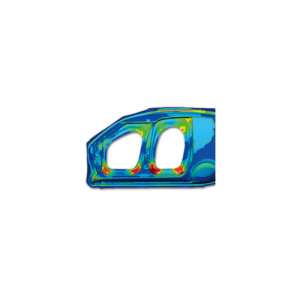

PAM-STAMP

.png)

PAM-STAMP 2G is a complete, integrated, scalable and streamlined stamping solution. It covers the entire tooling process including quotation and die design with formability and try-out validation, springback prediction and correction. It provides solutions-oriented tools for automotive, aerospace, and general stamping processes.