Yao Hung Technology Co., Ltd.

Yao Hung Technology team has more than 10 years of professional experience in the field of laser,leading product items:

YAG laser engraving machine, fiber laser engraving machine, fiber laser cutting machine, CO2 laser cutting engraving machine, large laser cutting machine, laser welding machine, laser jewelry spot welding machine, and other metal and non-metal processing equipment Development, sales, education, training and maintenance.

The company maintains a friendly service attitude and provides customers with comprehensive and customized models of services. Continuous pursuit of more advanced optoelectronic technology and peripheral equipment such as laser and cutting, in addition to selling goods, seeking truth from facts, excellence, and stability is our consistent business philosophy.

- Laser Welding Machine for Fiber Optic Transmission

Laser Welding Machine for Fiber Optic Transmission

Energy feedback type fiber optic transmission laser welding machine.

Welding speed is fast, allowing users to complete processing orders with high efficiency and quality.

Compact structure ensures safe operation of the equipment.

Simple handling after welding reduces labor intensity.

Better beam quality and uniformity of welded joints.

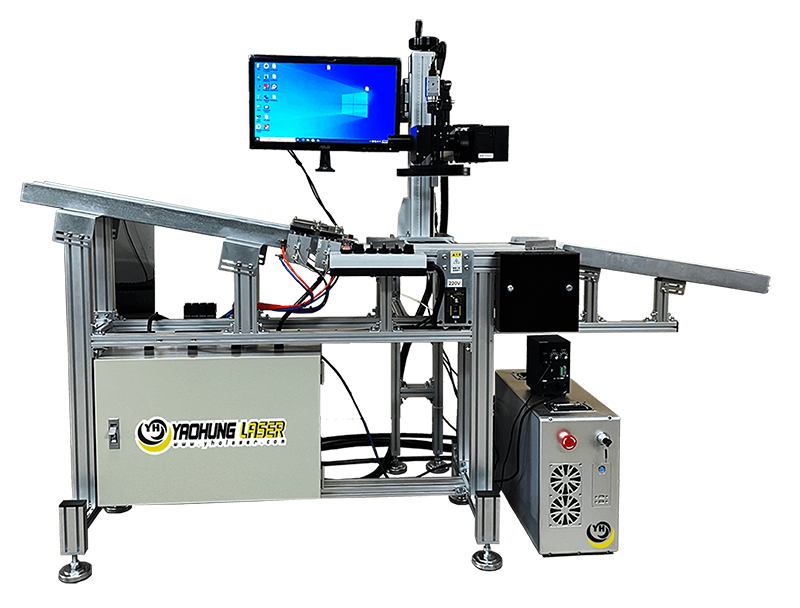

- 客製化打標機_輸送帶結合電腦視覺定位

Customized Marking Machine_Conveyor belts with computerized visual positioning

Air-cooled Cooling System.

Chinese language user interface.

Clear marking, not easy to wear, high engraving efficiency, environmental protection and energy saving.

High marking precision, high speed, controllable engraving depth, not easy to wear.

High laser power, suitable for engraving on various materials.

- 3D-Cabinet Type Auto Zoom Laser Cleaner

Aluminum profile design and processing, never rust, a large selection of universal independent module design, easy and fast maintenance.

Provide two kinds of laser heads for selection (gun type and standard type), provide focusing indicator red light, convenient for hand-held focusing operation, and exclusively provide quick knob to select seven different cleaning paths.

Expandable to multi-axis control automatic cleaning table, can be used in line with the workpiece automatic tracking cleaning samples.

Exclusive cleaning and deep marking system, two laser modes: general cleaning mode and non-invasive cleaning mode.

Waveform cleaning path (automatic phase change, angle automatic conversion), area automatic filling cleaning path, external import automatic CAD cleaning path.

.png)